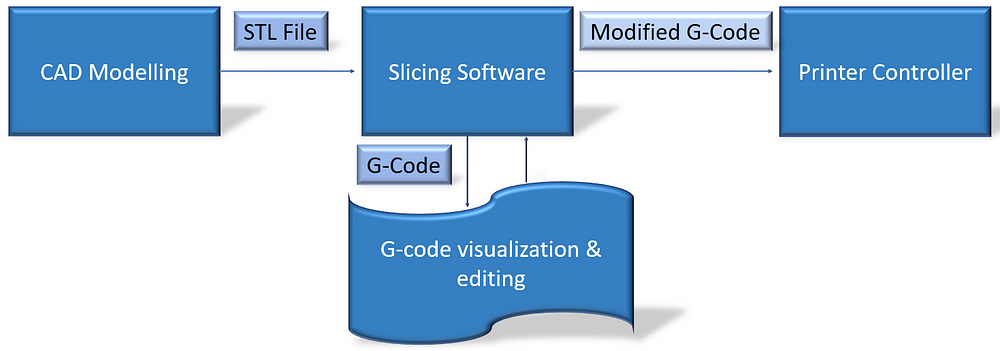

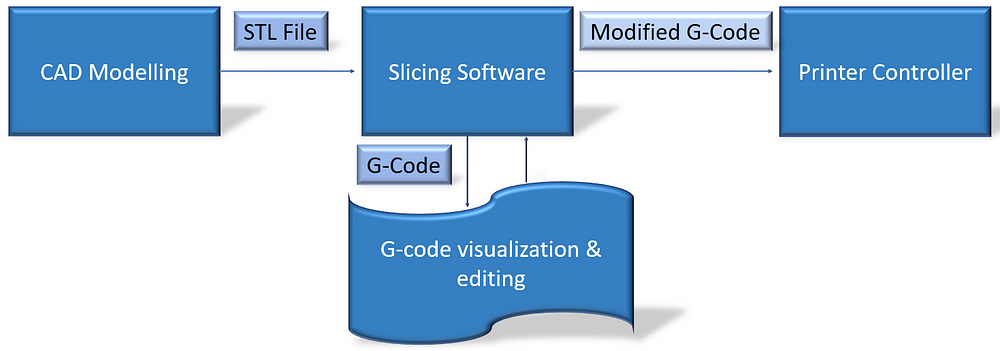

The act of converting a 3D model into a set of instructions for the 3D printers is called Slicing. Quite literally, it ‘slices’ the 3D model into thin layers, and further determine how each layer should be printed (the tool path) to get minimum time, best strength, etc.

The following website is a great resource to learn more about slicing.

What is the role of Slicing in 3D printing? - Fabheads

Cura is an open source slicing application for 3D printers.

👉🏿It was created by David Braam who was later employed by Ultimaker, a 3D printer manufacturing company, to maintain the software.

👉🏿Cura works by slicing the user’s model file into layers and generating a printer-specific g-code. Once finished, the g-code can be sent to the printer for the manufacture of the physical object

👉🏿Download Ultimaker Cura from official website

Ultimaker S5 pro bundle

This is the 3D printer available in Fablab CUSAT.

I designed a Clamp in Fusion 360, sliced it in Cura and printed it with Ultimaker S5.

This is the .stl file I designed in fusion.

Slicing in Cura

Printing in Ultimaker

KIRI

KIRI Engine is a free-to-use photogrammetry app, it uses cloud computing to deliver full-power 3D scanning to smartphones.